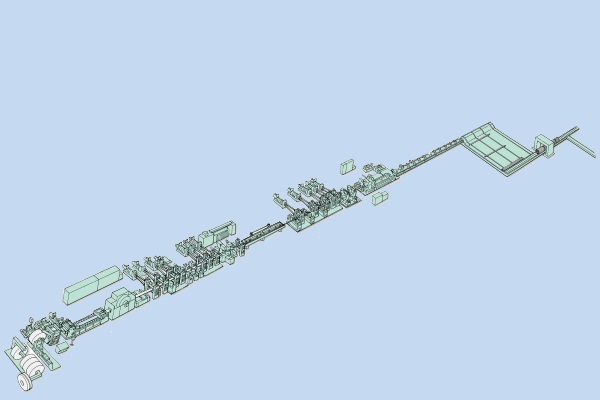

The manufacture of aluminum alloy radiator tubing requires a dedicated, high speed, precision tube mill for tubing diameters and profiles up to 20mm. Due to the mechanical properties of the thin aluminum strip the precision in the mill drives and the speed matching of the various components of the tube mill are extremely high. Add to this the required precision of the mechanical components resulting in a tube mill of outstanding quality. Kusakabe’s high level of engineering and design skills and experience makes the Kusakabe radiator tube mill the mill of choice of many manufacturers around the world.

Finshing Equipment

Cut Off

Sizing mill

Welding Station

Forming Mill

Looper

Strip Entry Equipment

| Strip Entry Equipment |

Looper

Accumulator |

Forming Mill |

Welding Station |

|

|

|

|

|

| Sizing Mill |

Cut Off |

Finshing Equipment |

|

|

|

|